Visual Inspection Products

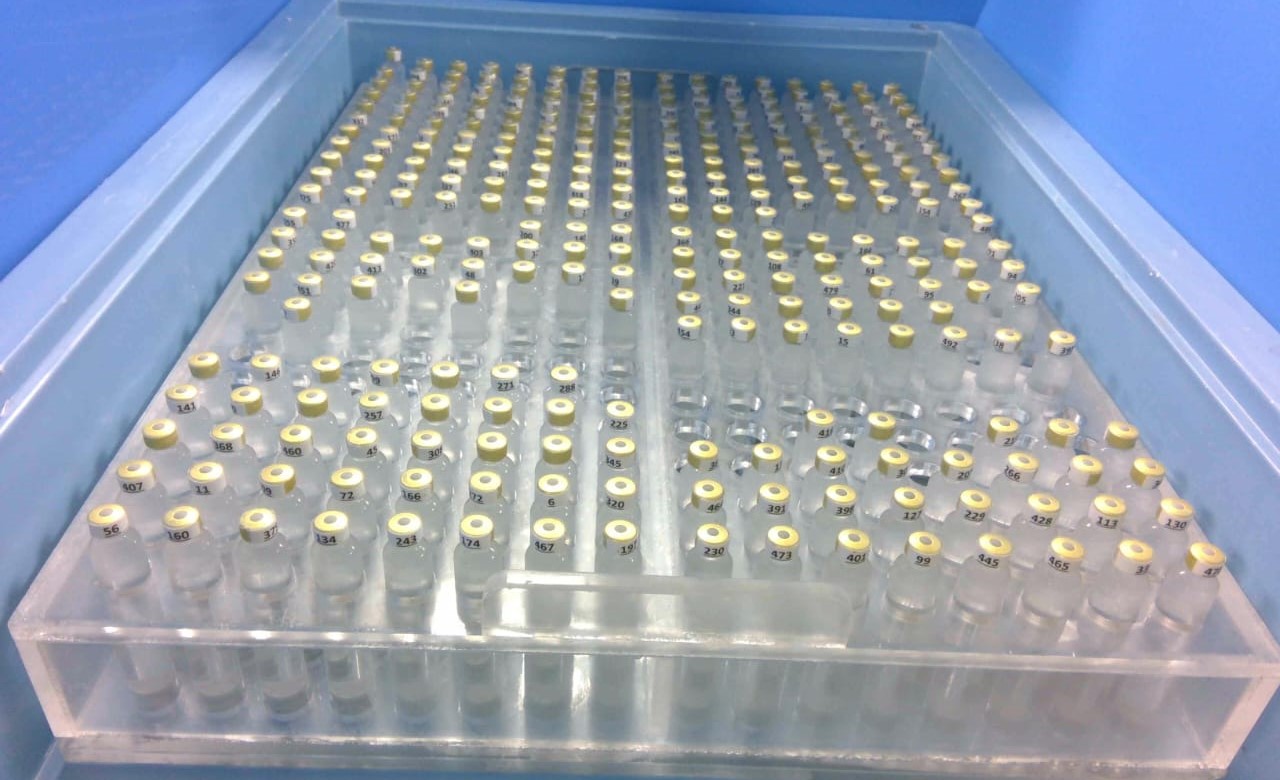

Knapp Kit, Manual Visual Inspection Kits, Particles, particulate Matters (Cost is Per Particle/Container)

Original price was: ₹3,000.00.₹2,600.00Current price is: ₹2,600.00.

Manual Visual inspection kits (Liquid and Lyophilized formulation with pack style of Vial, Cartridges and PFS) , Knapp kits for Manual and Automatic visual inspection machines, Particulate matters of different micron size range at very competitive price.

We are dealing with preparation of high standard Manual Visual inspection kits (Liquid and Lyophilized formulation with pack style of Vial, Cartridges and PFS) , knapp kits for Manual and Automatic visual inspection machines , Particulate matters of different micron size range at very competitive price. Kindly go through the attached catalogue for further details.

We are also offering the below services:

- Quality product with cost effective and timely deliverable

- Audit supportive documents with certificate of particulate matter

- Free replacement of any particle or containers, it may happen during transport.

- Audit response support – Requirement basis.

- Particle/Fibers sizing with certificates as per USP guidance and requirements.

- Onsite and Offsite Training on Visual inspection topic.

1.0 Defect description:

- Each particle & Fiber defect shall be created by highly trained and qualified technicians by using real source of Primary packaging material (PPM), Material used for machine parts/product contact part, Filter and garments used in Aseptic area.

- Each particle shall be washed and dried before using.

- Each particle shall be measured through a ( 3 dimensional) high resolution & high density digital microscope.

- Each particle shall be packed with a suitable slide (upper & Lower) or suitable air tight container.

- Technical team of IP solution shall guide to your team to seed the particle inside the container or any other type of queries.

- It is recommended to have Terminal sterilization of containers for longevity of kits.

2.0 What you will get:

- Defect kit shall be properly packed in a hard corrugated box.

- One UV torch for defect number identification (Complimentary as free of cost).

- Master Certificate of each defect kit.

- Probability of detection (POD) evaluation sheet (Each container 10-time inspection).

- Free replacement of defect container upon found non-viable of defect (Occasionally it happens during transportation).

- Any type of regulatory queries on kit (Online support to be provided by experts 24 X 7).

- KIT expiry certification: 2 to 3 Years (Based on Formulation).

3.0 How IP Solution is better than other Global supplier:

- One Day training by qualified visual inspectors at IP Solution lab-Vadodara. .

- Longer self-Life.

- Technical support and special kit handling training at IP Solution lab-Vadodara.

- Particle/Fibers sizing with certificates as per USP guidance and requirements.

- Quality product with cost effective and timely deliverable

- Audit supportive documents with certificate of particulate matter

1 review for Knapp Kit, Manual Visual Inspection Kits, Particles, particulate Matters (Cost is Per Particle/Container)

No product has been found!

Waseem Khatib –

Nice product